How Do Different Fire Hose Components Affect Emergency Response?

Firefighting relies on efficient equipment to ensure safety and effectiveness during emergencies. While many focus on the hoses themselves, the connectors and caps are equally important. Components like Storz Quick Coupling, Quick Release Fire Hose, and Threaded Fire Hydrant Cap play crucial roles in maintaining smooth operations, minimizing delays, and ensuring reliable water flow. Understanding their functions, applications, and differences can help fire departments optimize performance without overcomplicating equipment management.

The Importance of Fire Hose Components

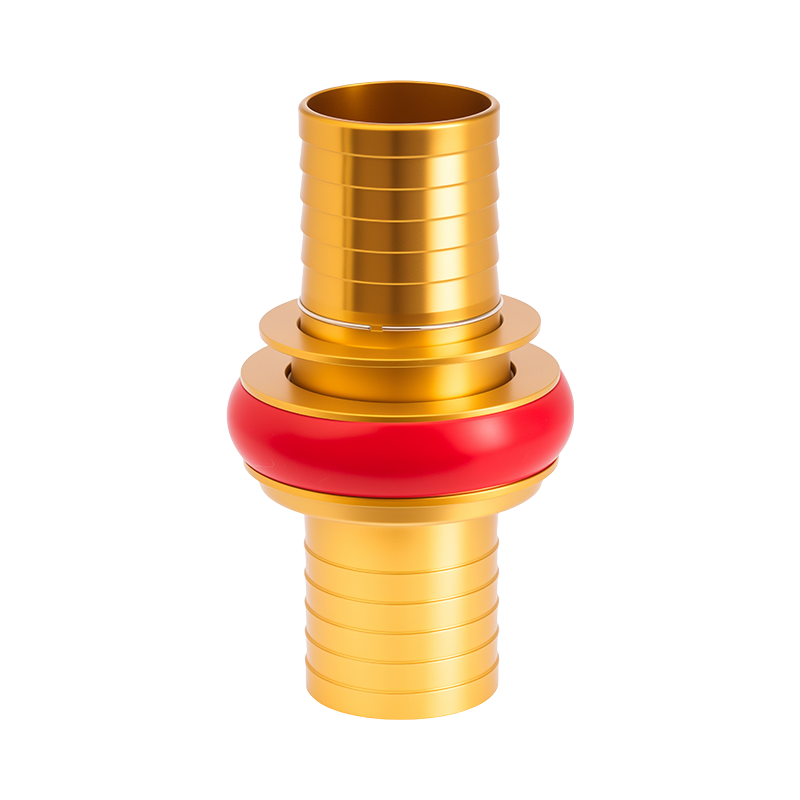

A fire hose is only as effective as the components that connect it to hydrants and other water sources. A Storz Quick Coupling is a type of connector widely used for its rapid attachment and detachment capabilities. Unlike traditional threaded connections, a Storz coupling allows firefighters to connect hoses in seconds without worrying about aligning threads, which can save critical time during emergency response.

Similarly, a Quick Release Fire Hose is designed to connect and disconnect efficiently from hydrants or pumps. These hoses usually feature mechanisms that allow fast operation while maintaining a secure seal, preventing leaks under high pressure. Quick-release functionality is particularly valuable in scenarios where multiple hoses need to be deployed quickly, such as large-scale urban fires.

The Threaded Fire Hydrant Cap, in contrast, serves a protective role for hydrants. It ensures the hydrant outlet remains free from debris, dust, and tampering. The threaded design allows a tight seal, preserving water pressure and reducing the risk of leakage. While it may take slightly longer to remove compared to quick couplings, the cap is reliable and durable for long-term protection.

Key Differences Between Components

Though all three components contribute to firefighting efficiency, they differ in design, function, and application:

|

Component |

Type | Main Advantage | Common Usage |

| Storz Quick Coupling | Quick-connect | Fast attachment and detachment |

Urban firefighting and rapid deployment |

| Quick Release Fire Hose | Hose with release | Quick connection without tools |

Emergency response requiring speed |

| Threaded Fire Hydrant Cap | Screw-on cap | Protects hydrant outlet and maintains pressure |

Municipal hydrants, long-term protection |

This table highlights that the selection of equipment depends on operational priorities. Rapid-response teams often rely on Storz Quick Coupling and Quick Release Fire Hose, while municipal hydrants frequently use Threaded Fire Hydrant Caps for security and water conservation.

Materials and Durability

The durability of fire hose components directly affects safety and operational readiness. Storz Quick Couplings are usually made of aluminum or brass, providing a combination of lightweight handling and resistance to corrosion. High-quality manufacturing ensures they maintain a tight seal even after repeated use.

Quick Release Fire Hoses often incorporate reinforced rubber or synthetic materials, with fittings designed to withstand high pressure. The quick-release mechanism must be engineered for repeated operation without risk of failure. Regular maintenance is necessary to keep the mechanism functional.

Threaded Fire Hydrant Caps are typically made of cast iron, brass, or high-strength polymer. These materials provide long-lasting protection and help prevent damage to hydrant outlets from environmental exposure or accidental impacts.

Installation and Operation

Proper installation and handling are crucial for maximizing the efficiency of these components.

- Storz Quick Coupling: Firefighters should align the coupling properly and twist until the locking mechanism engages. It is important to ensure no debris obstructs the connection, as this can compromise the seal.

- Quick Release Fire Hose: The release mechanism must click securely onto the hydrant or pump outlet. Users should check for a tight seal to avoid leaks while maintaining the ability to disconnect quickly if needed.

- Threaded Fire Hydrant Cap: When installing, screw the cap onto the hydrant carefully, ensuring threads align and the cap seals completely. Avoid over-tightening, which could damage threads over time.

Following these guidelines helps maintain equipment readiness and reduces the risk of delays or failures during emergencies.

Operational Impacts

The choice of connector or cap can significantly affect firefighting efficiency. A Storz Quick Coupling allows teams to deploy hoses rapidly, reducing setup time and enabling multiple teams to operate simultaneously. A Quick Release Fire Hose further enhances speed and flexibility, particularly in complex operations requiring frequent hose adjustments.

Meanwhile, a Threaded Fire Hydrant Cap may not provide the same speed, but it ensures hydrants remain clean and functional. Its reliable seal protects water pressure, which can be critical during extended firefighting operations. By combining these components strategically, departments can balance speed, safety, and reliability.

Maintenance and Inspection

Routine inspection is essential for all fire hose components. Storz Quick Couplings should be checked for deformation, corrosion, or damaged locking mechanisms. Even minor wear can compromise their quick-connect functionality.

Quick Release Fire Hoses require inspection of both the hose material and the release mechanism. Look for cracks, abrasions, or stiffness that might hinder performance. Lubrication of moving parts can improve reliability and extend lifespan.

Threaded Fire Hydrant Caps need attention to ensure threads remain intact and the cap seals properly. Any sign of corrosion or damage should prompt immediate replacement to avoid hydrant contamination or water loss.

Training and Familiarity

Firefighters must be trained to use all three components effectively. Hands-on practice with Storz Quick Coupling ensures that crews can attach and detach hoses under pressure without errors. Training with Quick Release Fire Hoses familiarizes teams with rapid connection techniques, reducing deployment time.

While Threaded Fire Hydrant Caps are slower to remove, familiarity helps firefighters handle them efficiently and prevents damage to threads or the hydrant. Regular drills incorporating all three components build confidence and improve coordination during real emergencies.

Environmental and Cost Considerations

When selecting fire hose components, departments consider not only operational performance but also environmental and budget factors.

- Storz Quick Couplings may cost more initially due to precise manufacturing standards, but they save time in critical operations.

- Quick Release Fire Hoses involve slightly higher maintenance due to moving parts, yet they improve response flexibility.

- Threaded Fire Hydrant Caps are durable and cost-effective for long-term protection, reducing maintenance needs and water waste.

Balancing cost, durability, and operational benefits ensures that fire departments can maintain readiness without unnecessary expenses.

Integration into Firefighting Strategy

Choosing the right combination of fire hose components depends on the environment, team size, and expected emergency scenarios. Urban firefighting teams often prioritize Storz Quick Couplings and Quick Release Fire Hoses to move quickly through dense areas and connect multiple hoses efficiently.

Municipal hydrants in parks, industrial areas, or regions with limited supervision often benefit from Threaded Fire Hydrant Caps, which maintain water cleanliness and reduce tampering risks. Integrating these components strategically allows departments to address diverse challenges while maintaining high operational efficiency.

Fire hose components like Storz Quick Coupling, Quick Release Fire Hose, and Threaded Fire Hydrant Cap are critical to firefighting success. Each serves a distinct purpose: speed and flexibility, ease of deployment, or protective sealing. Proper selection, installation, and maintenance ensure reliable performance, while training ensures teams can operate effectively under pressure.

Understanding the differences and applications of these components helps fire departments optimize emergency response strategies. By balancing rapid deployment with durability and protection, departments can achieve efficient, safe, and reliable firefighting operations, ensuring that water is available when and where it is needed most.

русский

русский Español

Español Deutsch

Deutsch عربى

عربى