How Do Different Hydrant Caps Impact Fire Safety Operations?

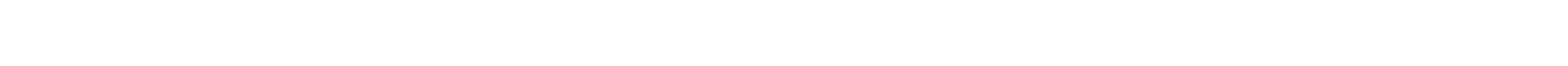

Fire hydrants are essential components of urban firefighting systems, providing a reliable water source for emergency situations. While many people are familiar with the hydrants themselves, the caps that protect them—such as Fire Hydrant Caps, Threaded Hydrant Caps, and Storz Hydrant Caps—play a crucial role in maintaining functionality, preventing contamination, and ensuring smooth firefighting operations. In this article, we will explore these types of hydrant caps, their features, and how they influence fire safety measures.

Understanding the Role of Hydrant Caps

Hydrant caps are not just simple covers. They prevent debris, dust, and foreign objects from entering the hydrant, which could compromise water flow during emergencies. A Fire Hydrant Cap typically protects the outlet, ensuring that firefighters can quickly attach hoses without worrying about blockages. In addition, it helps maintain water pressure by sealing the hydrant effectively when not in use.

Threaded Hydrant Caps function similarly but are designed with a screw mechanism that allows for a tight fit. This threading ensures the cap remains secure under various environmental conditions, such as strong winds or heavy rain. A secure cap reduces the chances of accidental water leakage or tampering.

On the other hand, Storz Hydrant Caps are used in systems equipped with Storz couplings. Unlike threaded caps, Storz caps do not screw on; instead, they utilize a quick-connect mechanism. This design allows firefighters to attach and detach hoses rapidly, which can save precious seconds in urgent situations.

Differences Between Fire Hydrant Cap Types

While all hydrant caps share the goal of protecting the water source, their designs and applications vary. Here's a quick comparison:

| Cap Type | Mechanism | Benefits | Common Use Case |

|

Fire Hydrant Cap |

Standard cover | Protects against debris and contamination | Municipal hydrants |

|

Threaded Hydrant Cap |

Screw-on | Secure fit, prevents leaks | Areas prone to vandalism or strong weather |

|

Storz Hydrant Cap |

Quick-connect | Rapid attachment and detachment | Firefighting teams needing speed |

From this table, it is clear that choosing the right cap depends on both environmental factors and operational needs. For example, a city hydrant located in a windy area might benefit from a Threaded Hydrant Cap, whereas a firefighting training facility may prefer Storz Hydrant Caps for their ease of use.

Materials and Durability Considerations

Hydrant caps are commonly manufactured from durable materials such as cast iron, brass, or high-strength plastic. A Fire Hydrant Cap made of cast iron provides robust protection against physical damage, while a plastic version is lighter and resistant to corrosion.

Threaded Hydrant Caps often require stronger materials for the screw threads to withstand repeated removal and installation. Brass or stainless steel is frequently used in these cases, as it provides long-term durability even under heavy usage.

Storz Hydrant Caps, given their quick-connect design, demand precise manufacturing standards. Any deformation in the cap can lead to a poor seal, affecting water pressure. Quality control during production ensures that Storz caps maintain consistent performance over time.

Maintenance and Inspection Practices

Routine inspection and maintenance of hydrant caps are essential for ensuring readiness. Fire departments typically follow a schedule that includes visual checks, cleaning, and lubrication when necessary.

A Fire Hydrant Cap should be checked for cracks or signs of corrosion, which could compromise its sealing ability. Threaded Hydrant Caps need additional attention to ensure the threads are not stripped or clogged, as this could prevent proper installation. Storz Hydrant Caps require inspection of the locking mechanism to guarantee a tight fit and prevent accidental disconnection during use.

Neglecting these checks can lead to minor issues that escalate during emergency operations. For instance, a stuck Threaded Hydrant Cap could delay water access, while a worn Storz Hydrant Cap might cause leaks under high pressure.

Installation Guidelines

Installing hydrant caps correctly is crucial for optimal performance. Here are some general guidelines:

- Ensure the hydrant outlet is clean before installing the cap.

- Align the cap properly: Threaded Hydrant Caps require precise engagement of threads, while Storz Hydrant Caps should click into the coupling securely.

- Avoid over-tightening threaded caps, which can damage the threads and reduce lifespan.

- Confirm the cap forms a full seal to prevent contamination and water leakage.

By following these steps, fire departments and municipalities can reduce maintenance costs and extend the lifespan of hydrant components.

Operational Impacts

Hydrant caps influence firefighting efficiency in subtle yet significant ways. A Fire Hydrant Cap that seals effectively ensures reliable water pressure, reducing the time firefighters spend checking for leaks. Threaded Hydrant Caps provide added security in areas where caps might be removed by unauthorized individuals. Meanwhile, Storz Hydrant Caps contribute to speed and flexibility, particularly in coordinated firefighting operations requiring multiple hose connections.

Choosing the appropriate hydrant cap can also affect emergency response planning. For example, regions with frequent natural disasters may prioritize Threaded Hydrant Caps for security, whereas urban centers with rapid-response teams may rely on Storz Hydrant Caps to minimize connection time.

Environmental and Cost Considerations

While functionality is paramount, environmental and budget factors also influence hydrant cap selection. Fire Hydrant Caps made from recyclable materials help reduce waste, whereas metal caps tend to last longer but may incur higher upfront costs.

Threaded Hydrant Caps may require more maintenance over time, but their secure design can prevent costly water loss. Storz Hydrant Caps, though often more expensive initially due to precise manufacturing requirements, can streamline operations and reduce downtime during emergencies.

Municipalities often balance these factors by analyzing both the initial cost and long-term operational efficiency, choosing the type that aligns with their priorities.

Training and Familiarity

Firefighting personnel must be familiar with the hydrant cap types used in their areas. Training programs include hands-on practice with Fire Hydrant Caps, Threaded Hydrant Caps, and Storz Hydrant Caps to ensure smooth operations during actual emergencies.

A firefighter who has experience with Storz Hydrant Caps can connect hoses in seconds, while understanding the nuances of Threaded Hydrant Caps ensures they can avoid cross-threading or over-tightening. Regular drills help reinforce these skills and reduce the likelihood of errors during high-pressure situations.

Hydrant caps, often overlooked, are critical components in the firefighting ecosystem. From Fire Hydrant Caps that provide basic protection, to Threaded Hydrant Caps offering secure, tamper-resistant coverage, and Storz Hydrant Caps enabling rapid hose connection, each type serves a specific purpose. Proper selection, installation, and maintenance of these caps ensure reliable water access, operational efficiency, and overall fire safety.

Understanding the differences and applications of these caps allows municipalities and fire departments to make informed decisions, balancing cost, durability, and performance. Investing time in training and routine inspections further enhances readiness, ensuring that when emergencies arise, hydrants function as intended, and firefighting teams can respond effectively.

русский

русский Español

Español Deutsch

Deutsch عربى

عربى