How Are Fire Hose Spray Guns Used in Different Fire Scenarios?

Effective firefighting depends not only on water supply but also on how that water is delivered. The way a stream is directed, adjusted, or dispersed can affect visibility, safety, and fire suppression efficiency. Devices such as the Fire Hose Spray Gun play a key role in turning pressurized water into a controlled tool that firefighters can rely on in different situations. Whether dealing with open flames, smoldering materials, or cooling operations, spray and jet devices are central to modern firefighting practice.

Why Water Control Matters in Fire Scenes

Fire scenes are dynamic. Flames spread, smoke shifts, and access routes change quickly. A steady stream alone is often not enough. Firefighters need the ability to adapt water output to match conditions on the ground.

An Adjustable Fire Nozzle allows operators to modify flow patterns without changing equipment. This flexibility helps crews respond to different fire behaviors while staying focused on safety and coordination.

Understanding the Fire Hose Spray Gun Concept

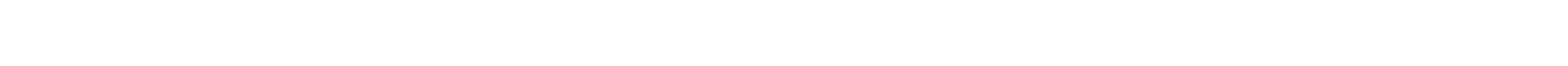

A Fire Hose Spray Gun is designed to provide controlled water discharge at the end of a fire hose. Unlike basic open hose ends, it allows firefighters to shape the stream, reduce fatigue, and maintain better control during extended use.

Typical Functions

- Directing water over longer distances

- Switching between straight stream and spray patterns

- Reducing recoil through ergonomic design

- Supporting continuous operation under pressure

These functions make spray guns suitable for both interior and exterior firefighting tasks.

How Adjustable Fire Nozzles Support Versatile Operations

Firefighting rarely follows a single pattern. An Adjustable Fire Nozzle is built to handle multiple flow modes within one device. By rotating or sliding a control ring, firefighters can change the spray angle or stream density.

This adaptability is useful when moving between tasks, such as knocking down visible flames and then switching to a wider spray for cooling surrounding surfaces.

Common Adjustment Modes

- Straight stream for distance and penetration

- Narrow spray for focused cooling

- Wide spray for heat absorption and protection

Adjustable nozzles help crews avoid unnecessary hose changes during critical moments.

The Role of a Fire Hose Jet Gun in High-Pressure Use

A Fire Hose Jet Gun focuses on producing a strong, concentrated water stream. This type of gun is often used when reach and impact are required, such as exterior firefighting or industrial fire scenarios.

Jet-style discharge is effective for:

- Reaching elevated fire areas

- Penetrating debris or dense smoke

- Supplying water to upper floors

Because of its focused output, proper handling and positioning are important to maintain stability and control.

Materials and Construction Choices

Spray guns and nozzles are typically made from aluminum alloys, brass, or composite materials. Each material offers different benefits depending on the application.

- Aluminum provides lightweight handling for mobile operations

- Brass offers durability and resistance to wear

- Composites reduce weight while maintaining structural strength

A well-designed Fire Hose Spray Gun balances strength with ease of use, especially during long response periods.

Ergonomics and Firefighter Safety

Handling high-pressure water for extended periods can be physically demanding. Ergonomic features help reduce strain and improve control.

An Adjustable Fire Nozzle often includes textured grips, balanced weight distribution, and smooth adjustment mechanisms. These features allow firefighters to maintain control even when wearing gloves or operating in wet conditions.

Good ergonomics also support teamwork, making it easier for multiple firefighters to manage a hose line together.

Comparing Spray, Adjustable, and Jet Functions

Although these devices are closely related, their usage scenarios differ slightly. The table below provides a general comparison:

| Feature | Spray Gun | Adjustable Nozzle | Jet Gun |

| Stream Control | Fixed or limited | Multiple adjustable modes | Focused stream |

| Typical Use | General firefighting | Mixed operations | Long-distance reach |

| Operator Effort | Moderate | Balanced | Higher due to recoil |

| Application Area | Interior and exterior | Flexible environments | Open or industrial spaces |

This comparison helps illustrate why departments often keep multiple options available.

Applications Across Different Firefighting Environments

Urban Firefighting

In city environments, interior operations are common. A Fire Hose Spray Gun supports controlled water delivery in confined spaces, helping manage heat while reducing water damage.

Industrial and Warehouse Fires

Large spaces often require long-distance water delivery. In these cases, a Fire Hose Jet Gun allows crews to attack fires from safer distances while maintaining stream integrity.

Wildland and Interface Zones

Although hose lines are lighter in these scenarios, adjustable discharge patterns remain valuable. An Adjustable Fire Nozzle can be used to create protective spray barriers or cool vegetation ahead of advancing flames.

Pressure Management and Flow Stability

Maintaining consistent pressure is critical for safe operation. Sudden changes in flow can cause hose movement or loss of control. Quality spray guns and nozzles are designed to handle pressure changes smoothly.

Flow regulation also helps conserve water, especially in areas with limited supply. Adjustable designs allow operators to use only what is needed for each task.

Maintenance and Inspection Considerations

Regular inspection extends the service life of firefighting equipment. Spray guns and nozzles should be checked for:

- Smooth adjustment movement

- Seal integrity to prevent leaks

- Nozzle opening wear or deformation

- Secure connection to hose couplings

Proper cleaning after use helps prevent buildup that could affect performance over time.

Compatibility with Fire Hose Systems

Fire departments often use hoses from different suppliers or of varying diameters. Spray guns and jet devices must be compatible with standard couplings used in the system.

A Fire Hose Spray Gun that supports common coupling standards reduces the need for additional adapters and simplifies deployment during emergencies.

Training and Operational Familiarity

Even well-designed equipment requires proper training. Firefighters need to understand how different stream patterns behave and when to use them. Training exercises often include switching between spray and jet modes under realistic conditions.

An Adjustable Fire Nozzle is especially useful in training, as it allows crews to practice multiple techniques using a single device.

Evolving Needs in Firefighting Equipment

As firefighting strategies evolve, equipment design continues to adapt. Lighter materials, smoother adjustment mechanisms, and improved flow control reflect changing operational needs.

While technology advances, the core purpose remains the same: giving firefighters reliable control over water delivery in unpredictable environments.

Water delivery tools are a critical link between supply and suppression. Devices such as the Fire Hose Spray Gun, Adjustable Fire Nozzle, and Fire Hose Jet Gun allow firefighters to adapt quickly to changing fire conditions while maintaining control and safety.

By understanding the strengths and applications of each design, fire departments can choose equipment that supports a wide range of scenarios. Thoughtful selection, regular maintenance, and proper training ensure that these tools continue to serve as dependable components in modern firefighting operations.

русский

русский Español

Español Deutsch

Deutsch عربى

عربى