How Do Hose Reducers Improve Firefighting Water Connections?

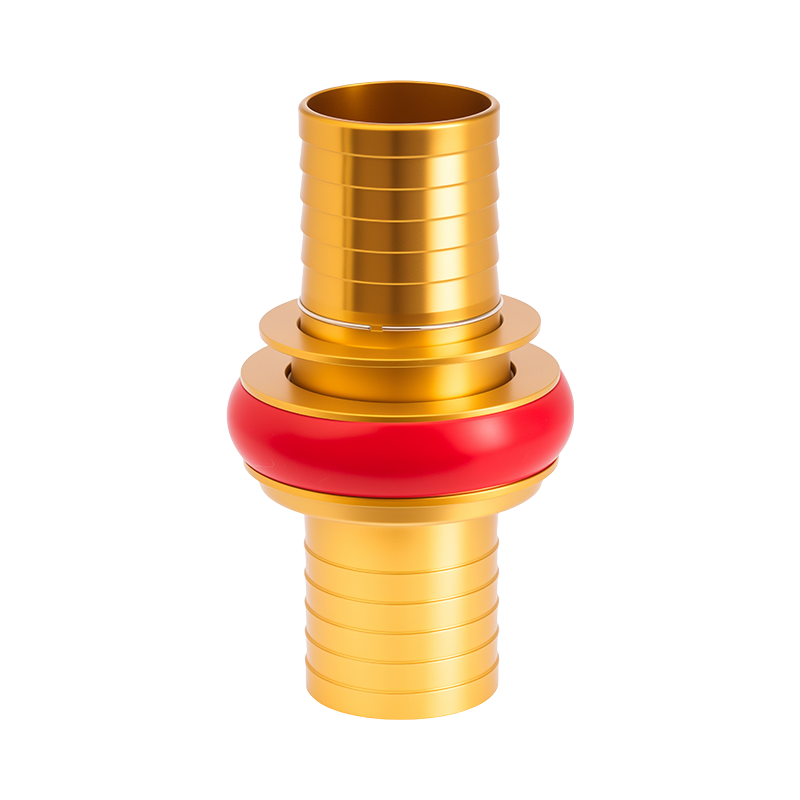

Firefighting systems rely on reliable hose connections to deliver water quickly and safely. In real-world operations, hose sizes and interface standards often differ between equipment, vehicles, and water sources. This is where connection reducers and adapters become essential. Components such as the Fire Hose Reducer help bridge these differences, allowing firefighters to adapt to changing conditions without interrupting water flow. Understanding how reducers and adapters work, and where they are used, is important for effective firefighting and emergency response.

Why Hose Size Transitions Matter in Firefighting

Fire scenes are rarely predictable. Fire engines, hydrants, pumps, and portable hoses may all use different diameters. Without a reliable way to transition between these sizes, valuable time can be lost. A reducer allows water to move from a larger hose to a smaller one, or vice versa, without major leakage or pressure loss.

In many fire departments, equipment from different suppliers must work together. Reducers and adapters support this compatibility, ensuring that teams can connect hoses quickly even when standards or sizes differ.

Understanding the Role of a Fire Hose Reducer

A Fire Hose Reducer is designed to connect hoses of different diameters within a firefighting system. It is commonly used when a high-capacity supply line needs to feed smaller attack lines closer to the fire scene. The reducer maintains a stable connection while allowing a controlled change in hose size.

Key Characteristics

- Supports smooth water transition between hose sizes

- Maintains pressure consistency during operation

- Designed for quick connection and removal

- Compatible with common firefighting hose materials

These features make reducers a standard component in both municipal and industrial fire protection systems.

How Storz Reducer Coupling Supports Fast Connections

The Storz Reducer Coupling is widely used in firefighting systems that require quick and secure hose connections. Unlike threaded couplings, Storz connections rely on a symmetrical design that allows hoses to be connected without alignment concerns. This reduces connection time, especially under stressful conditions.

Because the coupling is non-threaded, firefighters can connect hoses even in low-visibility environments. When used as a reducer, the coupling allows hoses of different Storz sizes to work together smoothly.

Common Applications

- Fire engines with multiple hose diameters

- Hydrant connections using Storz standards

- Portable pump setups

- Industrial fire protection systems

The simplicity of the Storz design helps reduce connection errors during emergencies.

What Is a Hose Tail Adapter Used For?

A Hose Tail Adapter is typically used to connect a hose to equipment such as pumps, valves, or tanks. One side of the adapter features a hose tail that fits inside or over a hose, while the other side connects to a threaded or coupling interface.

Hose tail adapters are often secured using clamps or crimping methods. This makes them suitable for semi-permanent or controlled installations where hoses remain connected for extended periods.

Typical Uses

- Fire pump outlets

- Water transfer systems

- Foam proportioning equipment

- Fixed fire suppression installations

In these settings, a hose tail adapter provides a reliable and straightforward connection method.

Comparing Reducers and Adapters in Fire Systems

While reducers and adapters serve different roles, both are essential for flexible hose management. The table below highlights general differences:

| Feature | Hose Reducer | Storz Reducer Coupling | Hose Tail Adapter |

| Primary Function | Change hose diameter | Quick size transition | Connect hose to equipment |

| Connection Style | Threaded or coupling-based | Symmetrical quick connection | Hose tail with clamp |

| Typical Use | Hose-to-hose | Hose-to-hose | Hose-to-device |

| Installation Speed | Moderate | Fast | Moderate |

| Common Materials | Aluminum, brass | Aluminum alloys | Brass, stainless steel |

Understanding these differences helps teams select the right component for each task.

Materials and Durability Considerations

Reducers and adapters are typically made from aluminum alloys, brass, or stainless steel. Aluminum is lightweight and commonly used in mobile firefighting equipment. Brass offers corrosion resistance and is often used in fixed installations. Stainless steel may be selected for harsh industrial environments.

A Fire Hose Reducer used in outdoor operations must withstand impact, moisture, and temperature changes. Material choice directly affects long-term reliability and ease of handling.

Pressure and Flow Performance

Maintaining water flow is critical during firefighting. Poorly designed reducers can cause turbulence or pressure drops. Quality components are shaped to guide water smoothly through the size transition.

The Storz Reducer Coupling is particularly effective in maintaining stable flow due to its consistent internal profile. Hose tail adapters also need proper sizing to avoid leaks or hose damage under pressure.

Installation and Handling in the Field

Ease of use is a major factor in emergency situations. Firefighters often work in gloves, low light, or high-stress conditions. Components that are intuitive and quick to handle reduce connection time and improve safety.

Reducers with clear markings and smooth surfaces are easier to identify and connect. Storz-style connections are favored in many regions because they eliminate threading errors. Hose tail adapters, while slightly slower to install, provide secure connections for equipment setups that do not change frequently.

Applications in Different Fire Protection Scenarios

Municipal Firefighting

Urban fire departments frequently use reducers to transition from large supply hoses to smaller attack lines. Storz connections are common on hydrants and engines, allowing rapid deployment.

Industrial Fire Protection

Factories, refineries, and warehouses often rely on fixed hose systems. In these environments, hose tail adapters connect hoses to pumps, tanks, or foam systems, while reducers manage flow between different hose sections.

Marine and Offshore Use

Firefighting systems on ships and offshore platforms require corrosion-resistant components. Reducers and adapters must perform reliably under constant exposure to moisture and salt.

Maintenance and Inspection Practices

Regular inspection ensures that hose connections remain reliable. Firefighters and maintenance teams should check for:

- Wear or deformation on coupling surfaces

- Corrosion or material fatigue

- Secure hose attachment on tail adapters

- Smooth locking action on Storz connections

Replacing damaged components before failure is essential for system safety.

Standardization and Compatibility

Firefighting equipment often follows regional or international standards. Storz systems are common in Europe and increasingly used elsewhere, while threaded connections vary by country. Reducers and adapters help bridge these differences, allowing equipment from different sources to work together.

A well-chosen Fire Hose Reducer improves compatibility without requiring complete system replacement.

Future Trends in Hose Connection Design

As firefighting equipment evolves, connection components continue to improve. Lighter materials, clearer size markings, and improved sealing designs help reduce errors and fatigue. Modular systems that allow quick reconfiguration are also becoming more common.

Storz-based systems are expanding due to their speed and ease of use, while hose tail adapters remain important for customized and fixed installations.

Reliable hose connections are a foundation of effective firefighting. Components such as the Fire Hose Reducer, Storz Reducer Coupling, and Hose Tail Adapter allow teams to adapt quickly to different hose sizes, equipment interfaces, and operational needs.

By understanding how these components function and where they are best applied, fire departments and industrial operators can build flexible systems that support fast deployment and stable water delivery. Thoughtful selection, regular maintenance, and proper training ensure that these small but critical components perform reliably when they are needed most.

русский

русский Español

Español Deutsch

Deutsch عربى

عربى